From the outside, United Parcel Service (UPS) is just a logistics company that delivers your packages from point A to point B.

But for a business leader like yourself, I don’t need to mention how messy logistics can get. Misplaced orders, package thefts, and excited customers who will quickly turn impatient if you don’t deliver on the promised date.

You’ve seen it all. It’s a challenge. But there’s always something new to learn every day.

Today’s edition is about another Fortune 500 company that is dominating the logistics industry by delivering over 25 million orders a day.

UPS operates in over 200 countries and territories with approximately 500,000 employees.

In today’s AI at the Top, we will learn how the 118-year-old company founded by teenagers uses AI across its business.

5 Ways UPS uses AI in its Business

1/ UPS built its proprietary tools: ORION and Dynamic ORION

In all of our editions, we keep talking about how data is the biggest advantage of legacy companies. They have been collecting information for decades (that’s more than some startups’ age). This data allows enterprises to unlock insights and make meaningful decisions.

ORION is another example of the “data moat”.

UPS built its proprietary tool, ORION (On Road Integration Optimisation and Navigation), to solve delivery route optimisation.

It was initially launched in 2003 and fully rolled out in 2012. ORION considered multiple factors like weather, traffic feeds, and package volumes, and set a static route for the day before the drivers left the warehouses.

But the world changes every second. Calculating for historical data is great, unless there is an accident on your route that requires a diversion. Or there is a concert attracting higher traffic than usual on some roads.

Understanding ORION’s limitations, UPS rolled out Dynamic ORION to not only calculate historic data but also real-time tracking of the packages and fleet. If there’s a last-minute customer request or a change in the weather, the system adapts automatically.

This sounds simple. But when you implement on a scale of a billion touch points per day, it saves UPS 100 million miles annually. That’s about $300-400 million saved a year and 10 million gallons of fuel annually.

2/ How UPS Achieved Package Precision with Smart Packaging

Now that the data moat is established, UPS is building its intelligent logistics network, a set of tools and use cases that learn from each other.

CEO, Carol B. Tomé, calls it “The Network of the Future.”

One of its initiatives is SPSF (Smart Packing Smart Facility).

Traditionally, logistics companies relied on bar code scanning at multiple checkpoints.

But by 2023, UPS embedded Radio Frequency Identification (RFID) tags on all of its packages. This removed the need to scan packages at each point and allowed continuous, precision tracking of the packages.

The package precision drastically reduced misplaced items. Also, it enabled UPS to build customer bots that could answer natural-language questions like “where is my order?”

3/ Logistics are unpredictable. This is how UPS deals with problems before they occur.

UPS uses Gen AI to create an exact replica of its end-to-end network.

This is a simulation environment for the enterprise to test complex “what if” scenarios. If there’s a weather forecast for a storm, UPS can test on its digital twin to measure the impact and take the necessary actions before the actual event occurs.

The NPTs (Network Planning Tools) enable UPS to test complex scenarios in an afternoon that previously took months.

4/ UPS uses DeliveryDefense to secure its deliveries

Package theft is a real thing. To deal with this, UPS partnered with Google Cloud to build DeliveryDefense.

The AI analyses delivery location type, historical theft frequency, and returns volume to assign each address a confidence score from 100 to 1000. Higher score indicates a safer delivery probability.

Merchants see low confidence scores and can automatically reroute at-risk shipments to secure UPS Stores or Access Point locations, preventing theft before it happens.

The data pipeline uses the Striim tool for real-time integration. It applies models from OpenAI and Google's Vertex AI to generate risk embeddings instantly.

Enjoying this read? Share the smartest part with your followers. Click to Share.

5/ AI and Robotics in the Physical World

All UPS technologies (ORION, SPSF, DeliveryDefense, etc.) share insights to make logistics more efficient. But the enterprise is not restricted to its online technologies.

UPS deployed over 1,400 robots across facilities to handle repetitive tasks. At the Velocity warehouse in Louisville, robots outnumber human workers 15:1. The automation increased productivity by up to 300% in certain processes.

The company is also testing general-purpose humanoids to lift boxes, sort packages, and transport goods to avoid expensive facility redesigns.

YOU DECIDE

🌟 Want to be featured in the next issue? Reach out with your best AI use case and we’ll spotlight it.

🏢 What company do you want us to cover next?

Strategic Partnerships

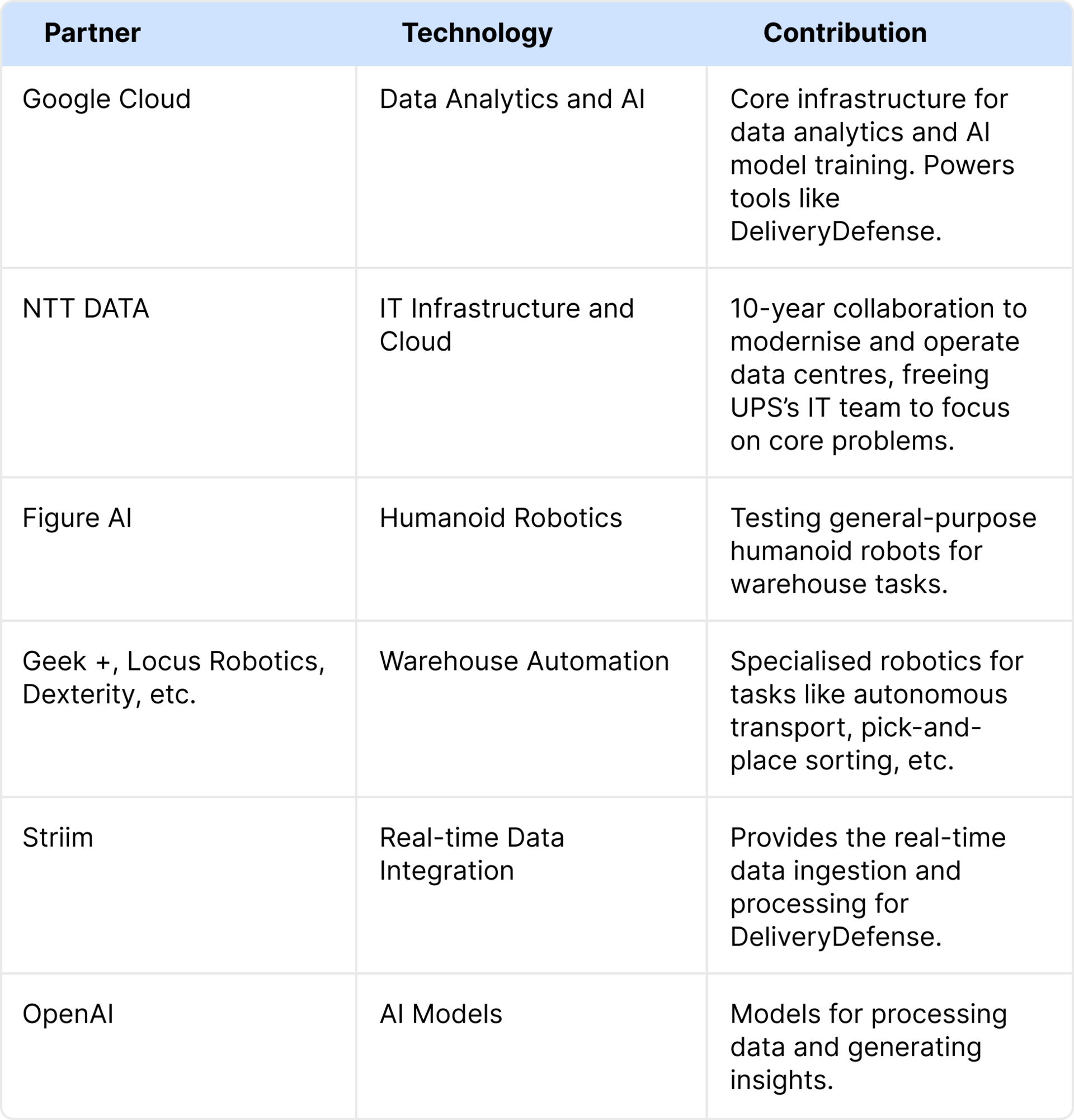

UPS partnered with companies like Google and OpenAI to achieve more with AI.

What’s next for UPS?

UPS is positioning for the next phase with fully agentic AI operations. Current systems optimise within defined parameters. The next generation will make autonomous decisions across multiple domains simultaneously.

CEO Carol Tomé mentioned the company is “leaning toward automation in ways we have never had before.”

UPS is also expanding their sustainability initiatives. The goal is complete carbon neutrality by 2050. AI becomes essential for hitting these targets through optimised routes and intelligent fleet management.

Sources:

Case studies and interviews by Klover, myHRfuture, Digital Defynd, Ascendanalytics, Millennial, Auroralive, and CDO Times.

Investor reports by UPS.

YOUR TURN